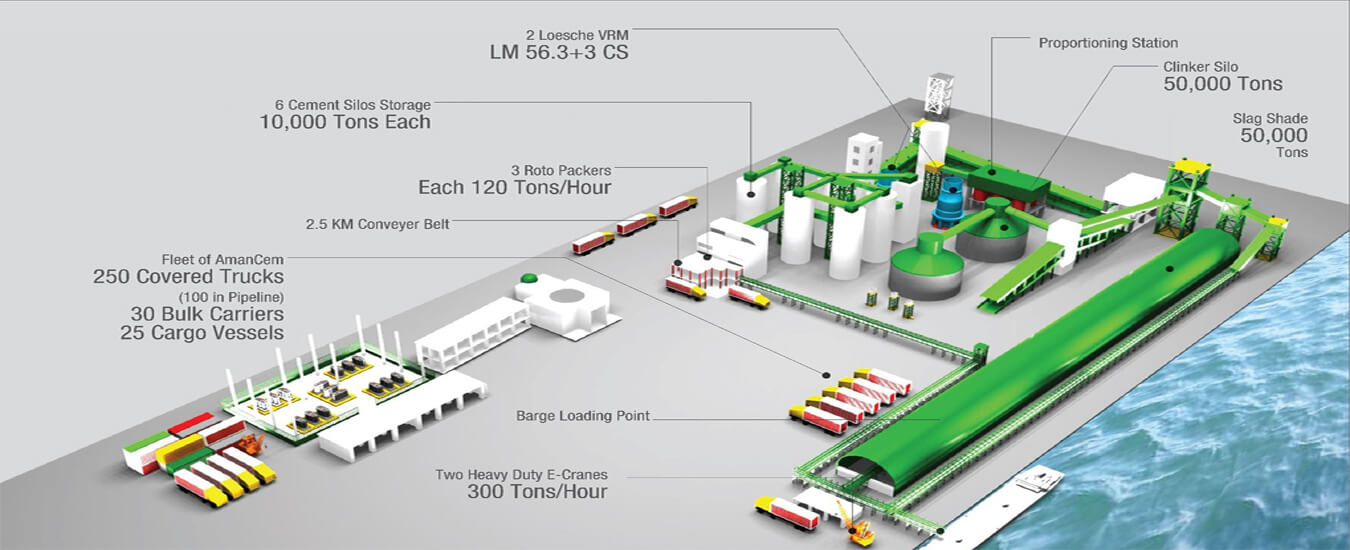

“AmanCem” with its unsurpassed quality, ready to meet country’s demand when the nation is going through the rapid development process. Today, AmanCem is one of the fastest growing and most promising cement company in Bangladesh. With state of the art technology, Aman Cement production capacity is 10,000 Metric Tons per day. With 3.5 million metric ton cement production, we are committed to fulfill nation’s infrastructure development demand and to export in the global market. To serve better and provide the best quality products to the nation, we selected the 4th generation cutting edge, latest & path breaking grinding technology from the LOESCHE Germany, the pioneer in Grinding Solution, since 1906; worldwide market leader in the business.

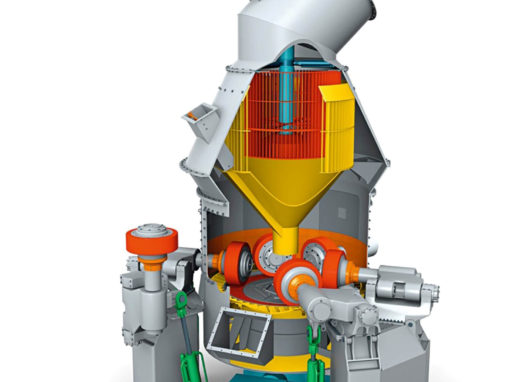

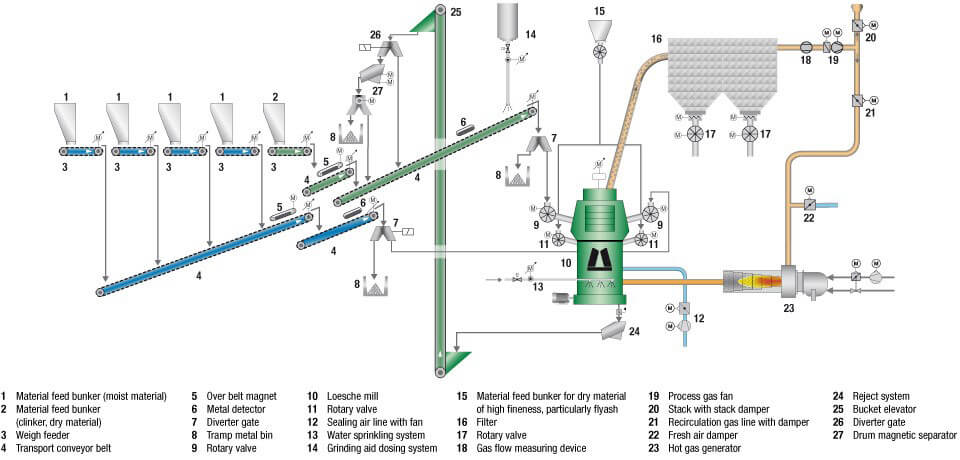

VRM (VERTICAL ROLLERS MILL)

LM 56.3+3 CS, the Mill size is identified according to the outer effective diameter of the grinding track in decimeters (dm). This specified the number of rollers operated in the mill. The number and size of rollers is geared to the required product throughput in conjunction with the performance factor as well as the product which is influenced by factors of grind ability, moisture and fineness.

At Aman Cement Mills Unit-2 Ltd, we have two VRMs

at 10,000 MT per day production capacity. Both VRMs are equipped with three pairs of grinding roller combinations, each consisting of a small support roller and a master roller. Due to the substantially finer grinding of cements to a residue value R45 of 5 -7% compared to ball mills, a support roller is therefore placed before each of the master rollers to prepare the highly aerated grinding bed for comminution.

CLASSIFIER

A defined product particle size distribution cannot be achieved without classification. We have highly efficient classifier in tandem with grinding technology.

HGG

For optimum combined drying & grinding results, we have hot-gas generator for burning solid fuels, low calorific value gases and conventional liquid and gaseous fuels.

E-CRANE

For smooth and continuous unloading of raw material like, Clinker, Gypsum, Slag, Limestone and Coal, we have 2 nos of E-Cranes which operate at 300 TPD each.

RAW MATERIAL SHED

Enviro-friendly 50,000 MT storage capacities and one of a kind single largest shed where Slag, Gypsum & Limestone are stored.

CLINKER SILO

50,000 MT storage capacities, concrete silo to store Clinker. Another 50,000 MT under construction.

FLY ASH SILO

5,000 MT storage capacities, concrete silo to store Fly Ash.

CEMENT SILO

10,000 MT each, storage capacity, 4 concrete silos to store various types of cement. Another two under construction.

ROTO PACKING MACHINE

The HAVER & BOECKER® Germany, is a rotating packing machine designed for packing cement at the high capacity. We have three another 2 is waiting for commission.

BULK DELIVERY MACHINE

Four bulk cement delivery machines each 120 TPH capacity, under each cement silos to deliver bulk cement to the custome

BARGE LOADING FACILITY

Barge loading facility to load cement bags @1500 cement bags per hour in to the barge for river transport.

FLY ASH UNLOADING FACILITY

State-of-the art unloading facility to unload bulk fly ash from the barge

QUALITY CONTROL FACILITY

We, at Aman Cement Mills Unit-2 Ltd, advanced equipment for quality testing of our raw materials as well as our various types of cement.

LOGISTICS

We have a strong fleet of 150 covered trucks and more 100 in pipeline, 30 dedicated bulk carriers, 25 light vessels to distribute cement nationwide and several ocean-going vessels to transport raw materials.

MANPOWER

16,000 dedicated, professional and an expert group of people from various local and global organizations to support this esteem institution.